Why do you need to change the air filter regularly?

Each air filter has its own initial resistance and final resistance. When the final resistance reaches a certain value, it needs to be replaced to ensure that the air in the environment can reach the prescribed level and avoid affecting production efficiency and quality.

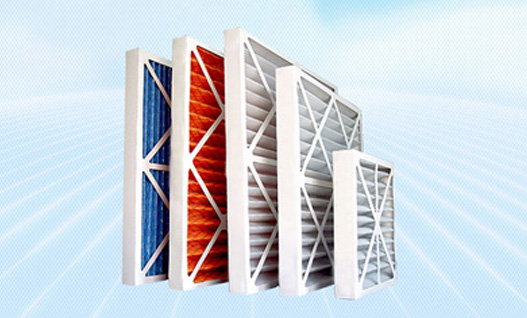

Benefits of changing air filters on a regular basis:

1. The filter box of each exhaust fan is required to open and check every half a year to see if the outer frame of the medium effect and high efficiency filter is damaged, and to clean and scrub the medium efficiency and the box, during which the cleaning standard of the medium efficiency net has strict rules.

2. All kinds of equipment shall be replaced according to the condition of damage, and the maximum service life shall not exceed 2 years.

3. If the high-efficiency filter is installed, open the chassis and check it every half a year to see if the high-efficiency filter is damaged, aging, actual effect and so on.

4. When replacing the high-efficiency filter, pay attention to the replacement according to the high-efficiency dust saturation, the replacement must be carried out strictly in accordance with the specifications of the production workshop, and the maximum service life of the high-efficiency filter shall not exceed 5 years.

5. Each time the replacement is effective, efficient, clean the chassis and daily observation, probably fill in the specific work records in time, and keep the file to be checked.

6. The storage method of the standby replacement medium-effect and primary-effect air filter is also exquisite, which should be packed in a plastic bag and sealed, placed in a special drying point, and should not be stacked or mixed with other items to prevent deformation and other questions. The model parameters of coarse filter screen (concave-convex mesh), initial filter screen, medium-effect filter and high-efficiency filter of each unit are subject to the record table.