What Are High Flow Box Filters and How Do They Work?

Table of Contents:

Section 1: What Are High Flow Box Filters?

Section 2: How Do High Flow Box Filters Work?

Section 3: Advantages of High Flow Box Filters

Section 4: Applications of High Flow Box Filters

Maintaining high air quality in industrial settings is crucial for the health and safety of workers, as well as the efficiency of operations.

Air filtration systems play a vital role in this regard, and among the various types of filters available, high flow box filters stand out for their efficiency and versatility.

What Are High Flow Box Filters?

Definition and Basic Description

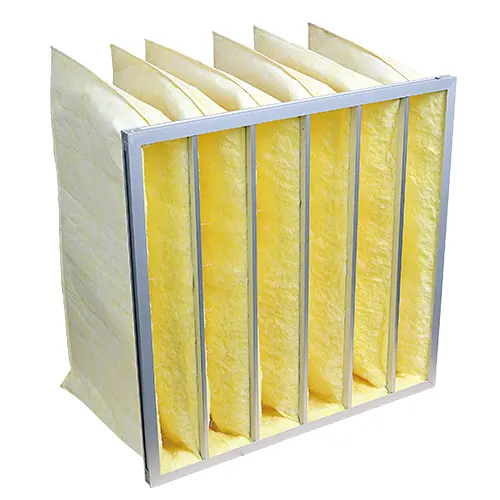

High flow box filters are a type of air filter designed to handle large volumes of air while maintaining low resistance to airflow.

These filters are integral to HVAC systems in both industrial and commercial settings, ensuring that air quality remains high without compromising the system’s efficiency.

They are particularly useful in environments where high levels of dust, particulate matter, and other airborne contaminants are present, as they provide effective filtration without quickly becoming clogged.

Key Features and Components

1. Large Surface Area: High flow box filters typically have an extended surface design, often achieved through pleating or other techniques, which increases the filter media area.

This large surface area allows for greater dust-holding capacity and longer intervals between filter replacements.

2. Low Pressure Drop: These filters are engineered to provide minimal resistance to airflow, which is crucial for maintaining the efficiency of HVAC systems.

A low pressure drop means that the system does not have to work as hard to move air through the filter, leading to energy savings and reduced operational costs.

3. High Efficiency Filter Media: The filter media used in high flow box filters is designed to capture a wide range of airborne particles, including dust, pollen, mold spores, and other contaminants.

The media is typically made from synthetic fibers or other durable materials that can withstand the demands of industrial environments.

4. Durable Construction: High flow box filters are built with robust frames and materials that can endure harsh conditions.

This durability ensures that the filters provide consistent performance over time, even in demanding settings.

How Do High Flow Box Filters Work?

High flow box filters are designed to efficiently clean large volumes of air in industrial and commercial HVAC systems.

The filtration process involves multiple steps to ensure that airborne contaminants are effectively captured while maintaining low resistance to airflow. As air passes through the filter, particulate matter is trapped in the filter media, allowing clean air to continue circulating through the HVAC system.

Mechanisms Involved in Capturing Contaminants

Exposure to poor air quality in industrial environments can cause both immediate and long-term health issues for workers, including symptoms like headaches, dizziness, and irritation of the eyes, nose, or throat. Prolonged exposure can lead to more severe conditions, significantly impacting productivity and increasing absenteeism due to illness.

Mechanisms Involved in Capturing Contaminants

1. Diffusion: In this mechanism, tiny particles collide with gas molecules and are diverted from their original path, increasing the likelihood of being captured by the filter fibers.

2. Interception: Particles following the airstream come into direct contact with the fibers in the filter media and are trapped upon contact.

3. Impaction: Larger particles collide directly with the filter fibers due to their greater inertia, becoming embedded in the filter media.

High flow box filters effectively remove contaminants from the air by utilizing these sophisticated filtration mechanisms, ensuring high air quality and efficient HVAC system performance.

Advantages of High Flow Box Filters

High Dust-Holding Capacity

High flow box filters are designed with an extended surface area, allowing them to capture and hold a significant amount of dust and particulate matter. This feature reduces the frequency of filter changes, making them cost-effective and efficient for environments with high levels of airborne contaminants.

Low Pressure Drop and Energy Efficiency

These filters are engineered to provide minimal resistance to airflow, which ensures that HVAC systems operate efficiently. The low pressure drop reduces the energy required to move air through the system, leading to lower energy consumption and cost savings for industrial and commercial facilities.

Durability and Long Service Life

Constructed with robust materials, high flow box filters are built to withstand harsh industrial conditions. Their durability ensures consistent performance over time, extending the service life of both the filters and the HVAC system, and reducing maintenance costs.

Applications of High Flow Box Filters

Industrial Settings

High flow box filters are designed with an extended surface area, allowing them to capture and hold a significant amount of dust and particulate matter in industrial settings, such as manufacturing plants, chemical processing sites.

This feature reduces the frequency of filter changes, making them cost-effective and efficient for environments with high levels of airborne contaminants.

Commercial Buildings

These filters are engineered to provide minimal resistance to airflow, which ensures that HVAC systems operate efficiently in offices, hospitals, and other spaces.

The low pressure drop reduces the energy required to move air through the system, leading to lower energy consumption and cost savings for commercial facilities.

Specialized Environments

High flow box filters are essential in specialized environments such as clean rooms and data centers, where maintaining stringent air quality standards is critical.

In clean rooms, these filters prevent contamination of sensitive processes and products, while in data centers, they protect electronic equipment from dust and particulate buildup, ensuring reliable operation and minimizing downtime.

Conclusion

High flow box filters are essential for maintaining high air quality in various industrial and commercial settings.

Their high dust-holding capacity, low pressure drop, and durable construction offer significant benefits, including cost savings, improved HVAC system efficiency, and enhanced health and safety for workers.

Incorporating high flow box filters into your air filtration strategy can ensure cleaner air and a more efficient working environment.

Contact CleanLink’s filtration experts for more solutions on your HVAC systems.