The Application of Bag Filters in Controlling Industrial Dust

Table of Contents:

Section 1: Understanding Industrial Dust

Section 2: What Are Bag Filters?

Section 3: Application of Bag Filters in Different Industries

Section 4: Best Practices for Maximizing the Efficiency of Bag Filters

Industrial dust is a significant concern for many industries due to its impact on human health, equipment longevity, and environmental safety. Effective dust control is not just a regulatory requirement but also a critical aspect of maintaining a safe and productive work environment.

Among the various methods available for dust control, bag filters have proven to be one of the most efficient and cost-effective solutions.

Understanding Industrial Dust

Industrial dust is a common byproduct of many manufacturing and processing operations. It consists of fine particles released into the air during various industrial activities. Understanding the sources, types, and impacts is crucial for implementing effective dust control measures and ensuring a safe and compliant working environment.

Sources of Industrial Dust

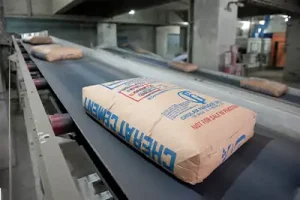

Cement Industry: The cement industry is one of the largest producers of industrial dust, with dust generated at different stages of production. This includes the handling and grinding of raw materials like limestone, clay, and gypsum, as well as during clinker production and the final grinding and packaging of cement.

Mining Industry: Dust is produced during drilling, blasting, crushing, and transporting ores and minerals. Surface mining operations, in particular, produce large amounts of dust that can spread over factory areas, impacting air quality onsite and in surrounding sections.

Food Processing Industry: During the handling and processing of dry ingredients like flour, sugar, spices, and grains, there will be dust emerge. Milling, mixing, and packaging processes can produce dust that poses health risks to workers and can influence the quality of final products.

Woodworking Industry: Dust is a significant concern in the woodworking industry, where sawing, sanding, and cutting wood generate large quantities of fine wood dust. This dust can pose serious respiratory risks for workers and lead to a combustible environment if not properly controlled.

Metalworking Industry: Metal dust is generated during production processes such as grinding, cutting, and polishing. The dust particles vary in size and composition depending on the type of metal processed, creating both health and safety risks if inhaled or accumulated in the workplace.

Types of Industrial Dust

Coarse Dust Particles: These are relatively larger dust particles, typically measuring between 2.5 and 10 microns in diameter. Coarse dust tends to settle fast and is often visible to the naked eye.

It is commonly produced during the grinding, crushing, and material handling processes. While coarse dust can cause mechanical wear and tear to equipment, its health impacts are generally less severe compared to finer dust.

Fine Dust Particles: Fine dust particles, also known as respirable dust, are smaller than 2.5 microns in diameter. These particles can remain airborne for a longer time and are more likely to be inhaled deeply into the lungs.

Fine dust is generated in processes like cutting, sanding, and milling. Due to its small size, fine dust is associated with more serious health risks, including respiratory diseases and long-term organ damage.

What Are Bag Filters?

How bag filters work

Bag filters are an important part of air filtration, designed to capture and contain dust particles from industrial air streams. They work by drawing contaminated air through fabric filter bags, where the dust particles are adsorbed on the surface or within the fabric.

Clean air then passes through the filter material and is released back into the environment or further processed. Over time, a layer of dust, known as a dust coat, forms on the filter, which can enhance its filtration efficiency by trapping even finer particles with higher energy consumption.

Advantages of Using Bag Filters

Bag filters offer several key advantages that make them an effective choice for dust control in various industries.

–>Highly efficient

->Cost-effective

->Capable of capturing a wide range of particle sizes

->Suitable for demanding applications.

->Inexpensive to install and maintain

->Can have a long operational life when properly cared for

->Can be used in different industrial settings

Application of Bag Filters in Different Industries

Cement Industry

In the cement industry, bag filters play a crucial role in controlling dust produced during various stages of production, including the handling of raw materials, clinker production, and cement grinding process. By trapping fine, powdery dust particles, bag filters help prevent air pollution, protect worker health, and ensure compliance with environmental regulations.

Metalworking and Foundries

In metalworking and foundries, operations like grinding, cutting, and welding generate significant amounts of metal dust and fumes. Bag filters are essential in these settings, effectively capturing airborne particles and fumes to protect workers from respiratory hazards and prevent the accumulation of hazardous dust that could lead to safety risks, such as fires or explosions.

Chemical and Petrochemical

The chemical and pharmaceutical industries often deal with fine and hazardous dust particles, including toxic substances. Bag filters are vital in these industries for capturing and containing these particles, preventing them from escaping into the environment or contaminating products. High-efficiency bag filters ensure that even the smallest and most dangerous particles are effectively controlled, supporting safe operations and regulatory compliance.

Food and Beverage Processing

Dust control is critical in the food and beverage industry to maintain product safety and quality. Bag filters are used to capture dust from processing dry ingredients like flour, sugar, and spices, ensuring that airborne particles do not contaminate products or create unhealthy working conditions. By maintaining a clean processing environment, bag filters help uphold industry standards for hygiene and safety.

Best Practices for Maximizing the Efficiency of Bag Filters

Proper Selection of Filter Media

Selecting the appropriate filter media is crucial for the efficient operation of bag filters. The media must be suited to the specific type of dust, whether it’s coarse, fine, or chemically reactive, to ensure effective dust capture. This careful selection helps optimize filtration performance and extends the lifespan of the filters.

Maintenance and Cleaning

Regular maintenance is essential to maintain the efficiency of bag filters. This involves routine cleaning to prevent excessive dust buildup, which can hinder airflow and reduce filter effectiveness. Additionally, periodic inspections help identify wear or damage early, allowing for timely repairs or replacements.

System Design Considerations

The design of the dust collection system significantly impacts the performance of bag filters. Proper airflow distribution and well-planned ductwork are key to ensuring even dust loading across all filter bags. Strategic placement of filters within the system further enhances efficiency and makes maintenance more manageable.

Conclusion

Bag filters are indispensable in controlling industrial dust, ensuring compliance with environmental and safety regulations, and protecting both workers and equipment.

Selecting the right filter, maintaining the filters properly, and paying attention to the performance of your HVAC system can help you maximize the efficiency and longevity of your bag filters.

Investing in quality bag filter systems is not just about meeting regulatory requirements—it’s about safeguarding health, improving operational efficiency, and contributing to a cleaner environment.

Contact CleanLink’s filtration experts for more tailored solutions for your applications.