Semiconductor

Semiconductor

In semiconductor fabs, the control of microcontamination is crucial for maintaining the integrity and efficiency of manufacturing processes.

Even the smallest contaminants can cause significant defects in wafer production, leading to reduced yields and increased costs.

As the semiconductor industry evolves with smaller device sizes and more complex processes, the need for effective contamination control has never been greater.

![]()

Challenges in Semiconductor Manufacturing

Airborne Molecular Contamination (AMC)

Airborne Molecular Contamination (AMC) is one of the most significant challenges in semiconductor manufacturing.

AMC involves the presence of airborne chemicals that can cause undesired reactions on wafer surfaces or within process equipment. These chemical reactions can lead to defects during chip production, reducing overall yield and affecting the performance an

Increased importance due to shrinking device sizes and demanding specifications

As semiconductor device sizes continue to shrink, and manufacturing specifications become more demanding, controlling AMC becomes increasingly critical.

Smaller devices are more sensitive to even minute levels of contamination, making stringent control measures essential.

The industry trend toward larger wafer dimensions amplifies the impact of AMC, as the cost of individual wafers rises, and the consequences of contamination become more severe.

Impact of larger wafer dimensions and high-cost defect-free masks

Another factor driving the importance of AMC control is the increasing use of high-cost, defect-free masks in advanced lithography processes, such as Extreme Ultraviolet (EUV) and multi-patterning Deep Ultraviolet (DUV) lithography.

These masks are crucial for achieving precise patterning on wafers, and any contamination can lead to costly defects and reduced manufacturing efficiency.

As a result, robust AMC control solutions are vital for maintaining high yields and minimizing the risk of contamination in semiconductor fabs.

![]()

CleanLink Offers Custom Air Filtration Solutions for Airports

CleanLink provides cutting-edge filtration solutions tailored to the rigorous demands of semiconductor manufacturing, ensuring optimal protection against contaminants.

Pre-Filters:

Our energy-efficient synthetic pre-filters are designed to protect critical HEPA and ULPA filters by capturing larger particles.

These pre-filters not only extend the life of your filtration system but also reduce energy consumption, contributing to lower operational costs.

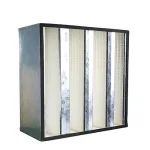

HEPA Filters:

CleanLink offers HEPA filters engineered to minimize the level of organic contaminants.

These filters are essential for maintaining the stringent air quality required in semiconductor cleanrooms, ensuring that even the smallest particles and volatile compounds are effectively captured.

AMC Control Solutions:

Airborne Molecular Contamination (AMC) control is critical in semiconductor fabs, and CleanLink’s AMC solutions have been rigorously tested both in the field and in laboratory environments.

Our filters are proven to provide superior protection against AMC, helping to prevent chemical reactions that can damage wafer surfaces and equipment.

By integrating these solutions into your manufacturing process, you can safeguard your production yield and maintain the highest standards of cleanliness in your cleanrooms.

![]()

Benefits of Using Air Filters in Semiconductor Manufacturing

Enhanced Process Yield

Air filters play a crucial role in reducing particle contamination within semiconductor fabs.

By effectively capturing airborne particles, these filters help prevent defects during wafer production, leading to a significant improvement in overall manufacturing efficiency.

Clean air ensures that each step of the process is free from contamination, which is essential for achieving high yields.

Protection of Equipment

Sensitive semiconductor manufacturing equipment is prone to wear and tear when exposed to contaminants.

Air filters minimize this damage by trapping harmful particles before they reach critical tools.

This protection not only extends the lifespan of the equipment but also reduces maintenance costs, ensuring that production remains smooth and cost-effective.

Compliance with Industry Standards

Semiconductor manufacturing requires adherence to strict cleanroom standards, such as ISO classifications, to maintain product quality.

Air filters help meet these stringent contamination control requirements by maintaining the necessary air quality levels, ensuring compliance with industry standards and regulations.

![]()

What to Expect from CleanLink’s Solutions

Energy Efficiency

CleanLink’s filtration solutions are designed with energy efficiency in mind.

Our advanced filters, including synthetic pre-filters and HEPA filters, help reduce energy consumption while maintaining optimal air quality.

This results in lower operational and maintenance costs and supports sustainable manufacturing practices.

Enhanced Process Yield

By effectively controlling airborne contaminants, CleanLink’s filtration solutions significantly enhance process yield.

Our filters protect critical semiconductor processes from contamination, reducing defects in wafer production and improving overall manufacturing efficiency.

Comprehensive Contamination Control

CleanLink offers a full range of filtration solutions that provide comprehensive contamination control.

From particle pre-filters to advanced AMC control solutions, our products ensure that your semiconductor manufacturing environment remains free from harmful contaminants, safeguarding both your equipment and your final products.