High-Quality Filters for Paint Booths Benefits: Improving Productivity and Results

Photo by Dylan Calluy on Unsplash

Photo by Dylan Calluy on Unsplash

Paint booth filtration systems play a vital role in various industries, ensuring the production of high-quality finishes while maintaining a safe and clean working environment. At the heart of these systems are high-quality filters designed specifically for paint booths. These filters, commonly referred to as filters for paint booths, are essential for capturing and removing airborne contaminants, such as overspray, dust, and particulate matter.

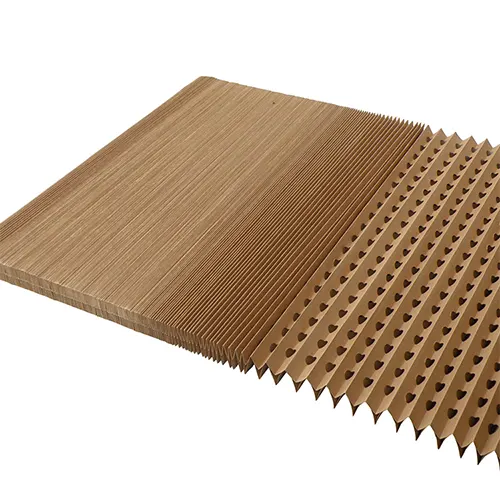

A key component of paint booth filtration systems is the selection of suitable air filter media. Air filter media refers to the materials used in constructing filters, which directly impact their filtration efficiency and effectiveness. Utilizing top-notch air filter media allows for the capture of even the tiniest particles, preventing their circulation within the paint booth and minimizing the risk of them settling on freshly painted surfaces.

The paint booth filtration system should be meticulously designed to ensure proper airflow, efficient particle capture, and effective ventilation. This involves considering the compatibility between the filters and the paint booth filtration system, ultimately aiming for optimal performance.

Understanding Paint Booth Filtration Systems

Paint booth filtration systems are essential for maintaining clean and safe working environments in various industries that involve painting operations. These systems are designed to capture and remove airborne contaminants, such as overspray, dust, and other particles, ensuring that they do not settle on painted surfaces and compromise the quality of the finish.

Components in a paint booth filtration system you should know

Air Circulation

Proper air circulation is crucial in a paint booth to ensure uniform distribution of clean air. It helps maintain a controlled environment, preventing the accumulation of contaminants and ensuring consistent airflow across the working area. Fans or blowers are used to circulate the air, creating a continuous flow that facilitates effective filtration.

Exhaust Systems

The exhaust system plays a vital role in expelling filtered air from the paint booth. It removes contaminated air, including overspray and volatile compounds, through exhaust fans and ductwork. By continuously extracting and replacing the air, the exhaust system helps maintain a clean and controlled environment within the paint booth.

Benefits of Using High-Quality Filters for Paint Booths

Photo by Dylan Calluy on Unsplash

Photo by Dylan Calluy on Unsplash

Improved Productivity with High-Quality Filters

When it comes to paint booth operations, productivity is of utmost importance. High-quality filters play a crucial role in improving productivity by creating a clean and controlled environment for painting processes. By effectively capturing and removing contaminants from the air, these filters contribute to a range of productivity-enhancing factors.

Firstly, filters ensure that the air inside the paint booth is free from particles and overspray, which can otherwise settle on painted surfaces and cause defects. This reduces the need for rework and touch-ups, saving valuable time and resources.

Secondly, clean air free from contaminants helps maintain the performance of painting equipment. Dust and particles can accumulate on sensitive components, affecting their efficiency and requiring frequent cleaning and maintenance. By using spray booth filters, the amount of contaminants entering the equipment is significantly reduced, leading to less downtime for cleaning and maintenance.

By reducing the need for frequent cleaning and maintenance, businesses can optimize their production schedules, leading to increased productivity and throughput. Employees can focus more on their core tasks, maximizing their efficiency and output.

Achieving Superior Paint Results

When it comes to achieving superior paint results, the quality of the air inside the paint booth plays a crucial role. High-quality filters are essential in maintaining clean air, free from contaminants that can compromise the paint finish. These filters effectively capture and remove particles, overspray, dust, and other airborne contaminants, ensuring a pristine environment for painting operations.

By using high-quality filters, businesses can minimize the presence of impurities in the air, preventing them from settling on the painted surface. This significantly reduces the risk of defects such as paint runs, fisheyes, or uneven coverage, resulting in a flawless and professional-looking paint finish.

Choosing the Right Filters for Your Paint Booth

Several factors to be considered

1. Filtration efficiency

Look for filters with high-efficiency ratings, such as HEPA (High-Efficiency Particulate Air) filters, which can capture and remove extremely small particles with great efficiency.

2. Compatibility with your paint booth system

Different paint booth systems may have specific requirements or restrictions when it comes to filter selection. Consult the air filter manufacturer‘s guidelines or seek advice from air filter media manufacturers to ensure you choose filters that are compatible with your paint booth equipment.

3. Air flow rate

Select filters that can handle the required air flow rate of your paint booth system without causing excessive pressure drop or restricting airflow. This ensures efficient ventilation and proper functioning of the paint booth.

4. Filter media

Different filter media offer varying levels of filtration and are designed to capture specific types of particles. For example, fiberglass filters are commonly used for general particle filtration, while activated carbon filters excel at removing odors and volatile organic compounds (VOCs). Assess your specific filtration needs and choose the appropriate filter media accordingly.

5. Filter service life

High-quality filters are designed to have a longer service life, which helps reduce maintenance frequency and replacement costs. Look for filters that are durable and can effectively maintain their filtration efficiency over an extended period.

Care for your filters, Care for your systems

Proper maintenance and regular inspection of filters are vital to ensure the optimal performance of your paint booth filtration system.

Over time, filters can become clogged with particles, overspray, and contaminants, which can hinder their effectiveness in capturing pollutants and maintaining clean air within the booth. Regular maintenance helps prevent filter clogging and ensures a consistent flow of clean air for your painting operations.

To maintain the effectiveness of your filters, it is crucial to follow proper cleaning and replacement practices. Start by inspecting filters regularly to assess their condition. Filters that are heavily loaded or damaged should be replaced promptly. For filters that can be cleaned, follow the manufacturer’s guidelines for proper cleaning methods and frequency.

Timely replacement ensures that the filters continue to deliver optimal filtration performance and maintain clean air quality.

Proper maintenance and timely replacement of filters offer numerous benefits for your paint booth and overall painting operations. By maintaining clean filters, you ensure consistent airflow and filtration efficiency, which directly impacts the quality of your paint finish. Clean filters help minimize the risk of particles settling on freshly painted surfaces, resulting in improved painting results and reduced rework.

Final Thoughts

Selecting high-quality filters for paint booths is essential for achieving optimal performance, improving productivity, and obtaining superior paint results. We have explored the importance of using filters specifically designed for paint booth applications and their benefits to your painting operations.

As you prioritize the selection of high-quality filters, you contribute to improved productivity, reduced equipment cleaning, and maintenance, and minimized downtime. By investing in air filter media from reputable manufacturers, you can have confidence in the performance and reliability of your paint booth filtration system.