Pocket Air Filters

Pocket Air Filters

Positioned as an integral component of modern air filtration systems, they offer a versatile solution capable of tackling a wide range of airborne contaminants.

Pocket filters serve as the first line of defense against dust, pollen, mold spores, and other particulate matter. This not only ensures the cleanliness of the air but also significantly enhances the overall indoor air quality, creating safer and more comfortable spaces for occupants.

Pocket Air Filters

Positioned as an integral component of modern air filtration systems, they offer a versatile solution capable of tackling a wide range of airborne contaminants.

Pocket filters serve as the first line of defense against dust, pollen, mold spores, and other particulate matter. This not only ensures the cleanliness of the air but also significantly enhances the overall indoor air quality, creating safer and more comfortable spaces for occupants.

How Pocket Filters Work

Structure and Design

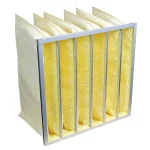

Pocket filters are ingeniously designed to provide high-efficiency air filtration. Their structure is characterized by a series of individual pockets. Each pocket is designed to expand, maximizing the surface area available for filtration without compromising the system’s airflow.

This unique configuration allows for a greater volume of air to pass through the filter while ensuring that particles are effectively trapped within the pockets. The materials used in the construction of pocket filters are chosen for their durability and filtration efficiency, ensuring that the filters can withstand the demands of various air handling systems and environments.

Filtration Mechanism

The filtration mechanism of pocket filters is a fine-tuned process that captures and removes airborne particles through a combination of physical interception and inertial impaction.

As air flows through the filter, larger particles are captured via direct interception by the filter media, while smaller particles are trapped through a process called inertial impaction, where the particles’ inertia causes them to embed themselves in the fibers of the filter media.

This dual-action filtration process allows pocket filters to efficiently remove a wide range of particle sizes from the air, including dust, pollen, mold spores, and other contaminants.

Types of Pocket Filters

Pocket filters are categorized primarily based on the media used in their construction: synthetic and fiberglass.

Synthetic pocket filters

Synthetic media pocket filters are known for their durability and high efficiency in filtering particulate matter.

They are moisture-resistant, making them ideal for use in environments with high humidity levels. Synthetic filters are also less prone to shedding fibers, ensuring cleaner air output and reducing the risk of contamination.

Fiberglass media filters

Fiberglass media filters offer excellent filtration capabilities, especially for smaller particles. They tend to have a higher dust-holding capacity, which can extend the service life of the filter. However, they may be more susceptible to damage from moisture and handling due to the brittle nature of fiberglass.

Benefits of Using Pocket Filters

High dust-holding capacity

Thanks to the unique design of pocket filters, which includes multiple individual pockets made from densely packed filtration media, they can trap and retain a large amount of particulate matter.

This capacity not only ensures a consistent removal of pollutants from the air over time but also extends the intervals between filter replacements, making pocket filters a cost-effective solution for maintaining indoor air quality.

Energy efficiency

The design of these filters is optimized to maintain maximum airflow while minimizing resistance. This means that HVAC systems equipped with pocket filters require less energy to circulate air through the filters, leading to lower operational costs.

The reduced strain on HVAC components also contributes to the overall energy efficiency of the system, making pocket filters an environmentally friendly choice for air filtration.

Long service life

Constructed from durable materials, these filters are designed to withstand the rigors of continuous operation without a significant loss of efficiency.

The robust structure of the pockets ensures that the filter maintains its shape and effectiveness throughout its usage cycle, reducing the need for frequent replacements.

Applications of Pocket Filters

HVAC Systems

Residential Buildings

Specific Environments

The demand for sterile air is paramount in some applications where air quality directly impacts health outcomes and the accuracy of sensitive experiments.

Pharmaceuticals

Choosing the Right Pocket Filter

Choosing the right pocket filter requires careful consideration of several key factors to ensure optimal air quality and system efficiency.

Airflow Requirements:

Choose a filter that matches the airflow capacity of your system to avoid excessive pressure drop and maintain energy efficiency.

Particle Size Filtration:

Consider the size of the particles you need to capture. Environments requiring the removal of very fine particles, such as hospitals or labs, need higher MERV-rated filters.

Expert Consultation:

Consulting with air filtration experts or manufacturers like Cleanlink can provide valuable guidance, ensuring you select a pocket filter that meets your air quality objectives while aligning with operational efficiency and cost-effectiveness.

Pocket Filters from CleanLink

Pocket filter material

CleanLink also manufactures filter bags for pocket filters. This bag material is a semi-finished product used to assemble pocket filters.